Genesis specializes in world-class custom automation solutions for manufacturing, inspection, assembly, and design. Our expertise is approaching your problem with a blank sheet of paper and creating a fully custom design uniquely tailored to your specific application. We have an accomplished team with years of experience in implementing one-off custom solutions in industries as far ranging as food packaging, automotive, textile handling, medical instruments, and many others.

Genesis is constantly improving our capabilities to match the demands of our industry, which is ever changing. As such, Genesis is ready to provide designs and machines that comply with modern, "Industry 4.0" design goals and trends, including remote monitoring, cloud-level data capture, and even centralized factory control systems.

Safety is a priority in all Genesis designs, with the inclusion and implementation of safety guarding and equipment being considered from the very first steps of the project. Where needed, Genesis can provide CE, UL and similar standards compliance to ensure regulatory conformity, and the safety of operators.

Whether you're looking for a complete production line, an individual work cell, or a retrofit of new equipment into an existing machine, we'd love to hear from you – if you can't purchase what you need off a shelf, our job is to help.

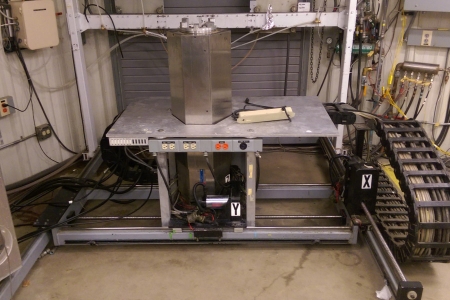

Individual Work Cells:

Many applications can be served by a stand-alone work cell. Typically, such machines will be a self-contained unit, requiring only shop air and power at the end-user facility. Every project is, of course different, but in most cases, Genesis will assemble and test such machines at our facility in Denver Colorado, and then ship the complete machine to the customer's facility for final installation.

Our stand-alone work cells are generally designed to run without operator supervision, with an operator only required to load and unload parts at regular intervals – these intervals are of course dependent entirely on your goals and needs.

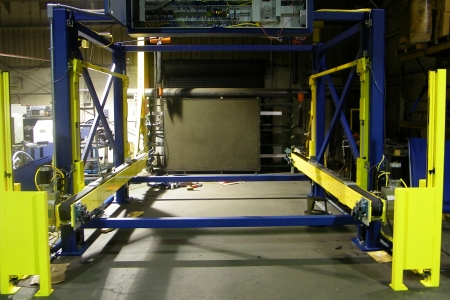

Complete Assembly Lines:

Some applications require a complete handling and production system, from raw material to a finished (or staged) product. In these situations, a complete assembly or handling line is the ideal solution. Genesis can work with you from start to finish to ensure our production line is perfectly tailored to making your specific product.

These installations are typically an amalgamation of custom work cells, off-the-shelf handling equipment, and a custom control system to ensure reliable and consistent operation. Genesis has completed multiple large-scale production line installations around the world, and we'd be happy to design and build yours too.

Due to the scale of these installations, they generally must be installed and tested at the end-user facility. The logistics of such projects will necessarily have to be worked out on a case-by-case basis.

Parts Handling & Inspection:

Modern industry demands fast handling and low failure rates. Shipping bad product results in wasted time and money, as well as a bad customer experience. In-process inspection, whether via vision, laser, or other sensors tailored to the application, is the best way to detect and correct or remove bad product before it leaves your facility. Genesis can help you integrate inspection capabilities into your existing system or create a work cell specifically tailored to inspect your parts. Since every part and process is unique, inspection stations should also be unique, to get you as much actionable data as possible. This data should be provided as quickly as possible, without lowering throughput. Genesis can additionally provide this data to other systems, such as Data Acquisition Units, Matlab, Industrial Controllers, Web Portals, SQL, or even to a manual inspector, so that you can have your data where you need it, when you need it.

Modern industry demands fast handling and low failure rates. Shipping bad product results in wasted time and money, as well as a bad customer experience. In-process inspection, whether via vision, laser, or other sensors tailored to the application, is the best way to detect and correct or remove bad product before it leaves your facility. Genesis can help you integrate inspection capabilities into your existing system or create a work cell specifically tailored to inspect your parts. Since every part and process is unique, inspection stations should also be unique, to get you as much actionable data as possible. This data should be provided as quickly as possible, without lowering throughput. Genesis can additionally provide this data to other systems, such as Data Acquisition Units, Matlab, Industrial Controllers, Web Portals, SQL, or even to a manual inspector, so that you can have your data where you need it, when you need it.

System Retrofitting & Rebuild:

Machines, like everything, get old and worn out. If you've got equipment that's on its last legs, Genesis can aid in bringing it into the modern era with new controls and repair or replacement of worn components. Chances are much of your hardware is still useable, and new controls can make your machine perform better than ever. A retrofit is also a great time to add new capabilities, whether that's simply increasing speed thanks to better control, or introducing new handling or inspection options.

Genesis has experience retrofitting machines of all types, ranging from 1900's era relay logic driven industrial equipment to modern equipment that didn't meet requirements, and just about everything in between. We are therefore uniquely suited to assess and evaluate your current systems and propose improvements, or to help you implement the improvements you have determined are necessary.

Web Handling:

Web handling applications are quite common in industrial processes, and they pose several unique challenges. Maintaining appropriate tension and web steering both take precise, real time control. Tracking the position of seams/splices, and product features through the web path requires absolute synchronization between the control systems, sensor inputs, and the web itself. Using Beckhoff TwinCat control systems, Genesis has created multiple successful custom large-scale web handling production lines.

Robotic Work Cells:

Robotics is a staple of modern automation. Many applications are well served by the flexibility and speed that modern robotic arms can offer. Genesis has experience integrating robotics into both small work cells and large-scale production lines. If a robot is a good fit for your application, we can make it happen.

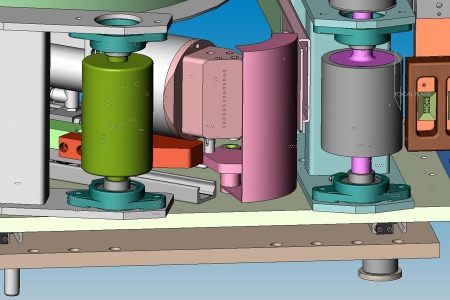

Custom Projects & Prototyping:

Sometimes you've got an idea and you don't know how to build it, or even if it can be built. With our many years of experience in production and custom equipment, Genesis is uniquely positioned to help you figure out how to make your idea into a product. We'll happily design and build the equipment to make your idea a reality, too!